Fukushima Solar Inc. is a venture capital and Minami-soma is a city in Fukushima prefecture where many people still suffer from Fukushima Nuclear Power Plant accident caused by big earthquake and tsunami in March 11th last year.

In this park they generate 500kW by solar panels.

100kW is used for agriculture in this park and remaining 400kW is sold to Tohoku Electric Power Co., Inc.

by Fukushima Solar Inc.

This scheme is aimed at revitalizing agriculture in this area by self-supplied energy.

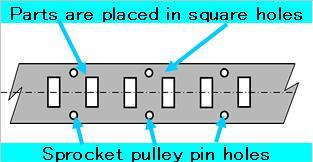

For details of steel belts in photovoltaic module production, go to

http://www.steelbelt.jp/product/stainlesssteelbelt/post_1.php

Steel belt video: http://www.steelbelt.jp/060video/video.php

Contact by email: overseas@dymco.co.jp

Facebook: http://www.facebook.com/dymco.limited

To all visitors to DYMCO at FILM TECH JAPAN 12.04.11-13,

To all visitors to DYMCO at FILM TECH JAPAN 12.04.11-13,